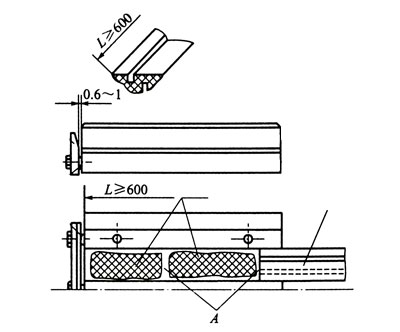

Improved strip rubber product bending

In the production of molded strip rubber products, due to the fluctuation of the weight error of the semi-finished products, especially when the weight is too high, it is easy to cause the products to be bent and bowed after being vulcanized at the point A. In order to avoid the above phenomenon, a metal washer of 0. 6~1mm thick can be placed on the side of the mold baffle and in the middle of each screw of the fastening baffle to avoid the above-mentioned disadvantages. The principle: when the product is vulcanized, the excess rubber is discharged from the gap outside the mold. Although it brings a certain flow of rubber, it does not affect the length of the product, which is beneficial to insert the cavity into the cavity and increase the bonding strength.

Long strip rubber products and molds